SPLITTER Saw

Certification: CE/ NSF

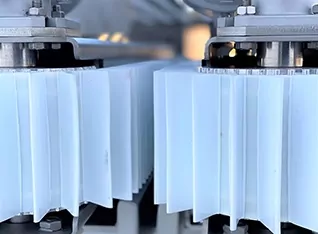

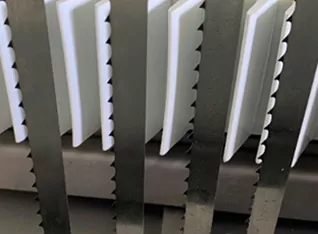

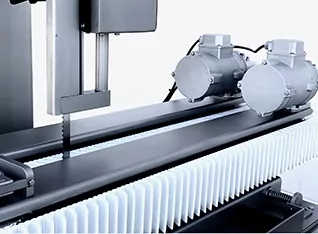

The SPLITTER with splitting conveyor has a saw which works in parallel provides a longitudinal cut

Splitting Conveyor

- Belt width regulation

- Speed regulation

Easy to Use

- Continuous cycle machine

- The product enter into the belts and comes out on the other side split

Security

- Security design

- Prevent your employees being hurt

Warranty

1 Year Standard Warranty

Financing Available

Orders Over $500

SPLITTER Saw

The production necessities are different depending on each company, and this is the reason why at Mainali this has been always the starting point, offering particular solutions adapted to the necessities of each client. Most of these applications can be both frozen or fresh.

1. Control Panel

Easy to use, convenient control panel with large button display including start / stop, emergency stop, and speed control.

2. Interchangeable Safety Entry Point

Mainali machines are built with 'safety first' standards, including this safety entry point for accident prevention.

3. Magnetic Locking System

This unique locking mechanism prevents unauthorized opening of the blade while the machine is running.

4. Catch Bin

Easy and convenient bin to access residue, fragments, and bone dust. Machine will not operate without the bin in place.

5. Blade Tension Pulley

This pulley allows the user to provide various levels of tension to the blade. Easy to access, doesn't require opening up the machine as others on the market.

6. Safety Covering Case

Removable stainless steel frame with plexiglass casing for easy visibility of the product moving through the conveyor system.

7. Damped Adjustment System

Quick access to adjust the width of the belt from the outside of the machine to reduce downtime, rather then disassembling the machine to make adjustments.

1. Cutting Edge Safety Sensors

Introducing our cutting-edge magnetic safety sensor technology. A reliable and versatile solution that ensures the utmost safety in a wide range of applications. You and your staff can experience the latest in safety technology.

2. Robust Product Hopper

Introducing our robust product hopper, designed to handle large volumes with ease. Its spacious capacity holds up to 50 pounds of product and ensures uninterrupted production, allowing for efficient and continuous workflow.

3. Time Saving Paper Applicator

Discover the game-changing optional paper applicator that streamlines your workflow, saving you valuable time and money. Its seamless integration with our equipment ensures precise and efficient paper application between patties thus reducing waste, maximizing productivity and perfectly separating your portions.

4. Convenient Power And Speed Control

Unleash the power of our equipment with the push of a button ensuring ultimate convenience and safety in your professional kitchen. Control the speed effortlessly tailoring the machine's performance to your unique needs. Precision and convenience every time.

5. Efficient Outfeed Belt

Experience unparalleled efficiency with our optional outfeed belt, designed to optimize your production process. Streamline your production by seamlessly integrating with our products ensuring smooth a continuous product flow, eliminating bottlenecks and increasing overall productivity.

6. Effortless Portion Control

Take control of portion precision with our innovative portion controls. Designed to accurately measure and dispense precise amounts, they empower you to minimize waste, maintain consistent serving sizes, and maximize cost efficiency for your business.

7. Quick Release Controls

Intuitively designed, convenient quick release controls engineered for effortless disassembly. With a simple and easy to use design, you can easily dismantle and clean our equipment, saving valuable time and ensuring optimal hygiene standards.

8. Customizable Product Forming Plates

Unlock endless possibilities with our customizable product forming plates. Tailor-made to meet your unique needs, these plates allow you to create a wide range of product shapes and sizes, offering versatility and flexibility to achieve your desired outcomes. Revolutionize your production process and unleash your creativity with our innovative customizable product forming plates.

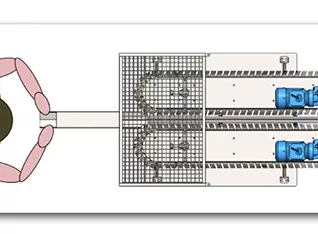

The SPLITTER with splitting conveyor has a saw which works in parallel provides a longitudinal cut. The conveyor track with variable speed and easy regulation of the belt helps to get a better adaptation to the product. It is a continuous cycle machine, com-pact and easy to use. The operator has to enter the product into the belts and it comes out on the other side split.

Furthermore, it has a security design that save your company from OSHA fines from employees being hurt on meat band saws.

Technical Data

Splitting conveyor

Maximum adaptibility to the product

Longitudinal cut

Perfect longitudinal cut.

Continuous cycle

Do no waste time in transitions

Safe

Maximum security for operators.